Resin cure shrinkage stress measuring device

JIS Standards JIS K 6941 Enactment

We have established JIS measuring standards using our product Custron (resin curing shrinkage rate measuring device).

“Continuous measurement method of shrinkage ratio of JIS K6941 UV curable resin and thermosetting resin”

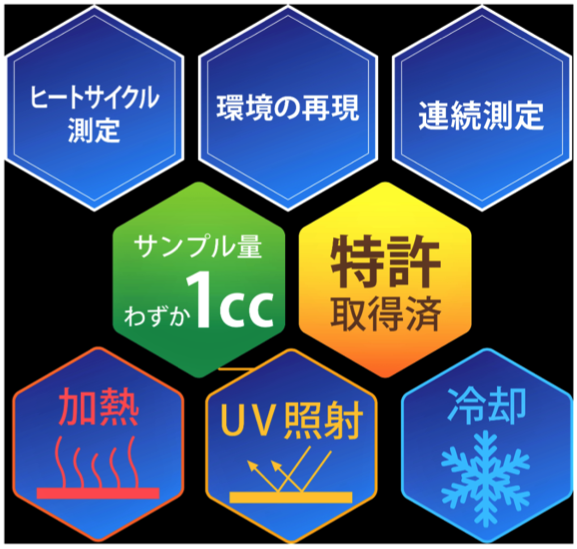

Features

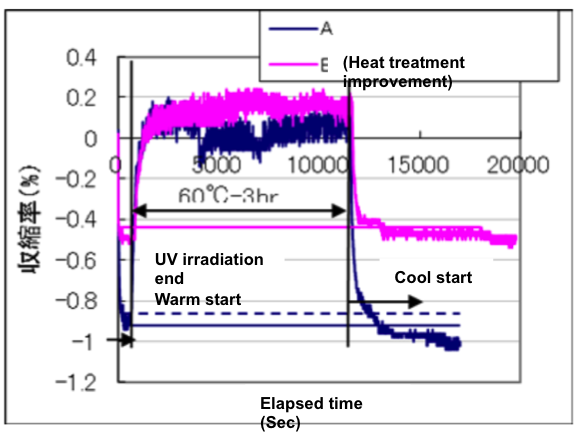

Continuous measurement of all processes before → during → after reaction

UV curing resin · thermosetting resin ·

Continuous measurement of cure shrinkage and shrinkage stress associated with curing of epoxy resin, UV adhesive, UV ink, coating, wax, etc.

Heat cycle measurement

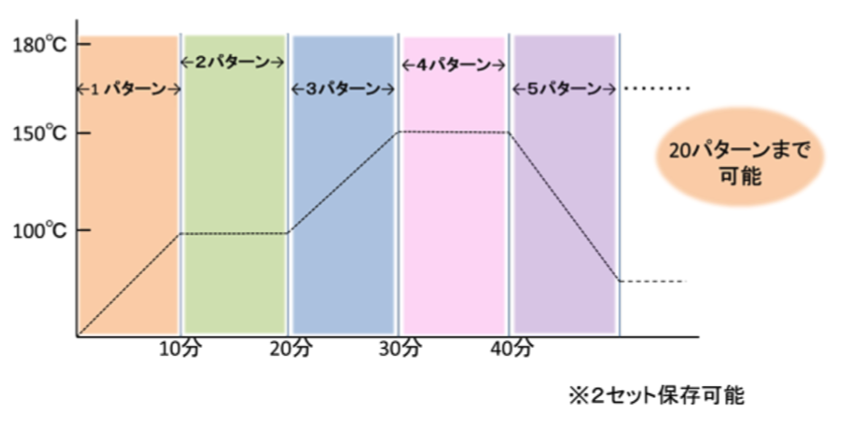

It is possible to freely set the thermal profile of temperature rise and fall temperature such as UV irradiation → heating → cooling by program (normal temperature to 180 ° C)Reproduction of the environment

Reproduction of the environment

Reproduces the rate of shrinkage and shrinkage stress that a product placed in various environments receives during the product manufacturing process or when it is exposed to various heat during long-term aging

Temperature change of resin surface can be measured

Sample amount is small (1 cc) and OK

No need for special measurement techniques

About optional items

Types that allow temperature setting from -50 ° C to 150 ° C · Types that allow temperature setting from room temperature to 300 ° C · Nitrogen purge · Sample temperature measurement function.

Please contact us for details.

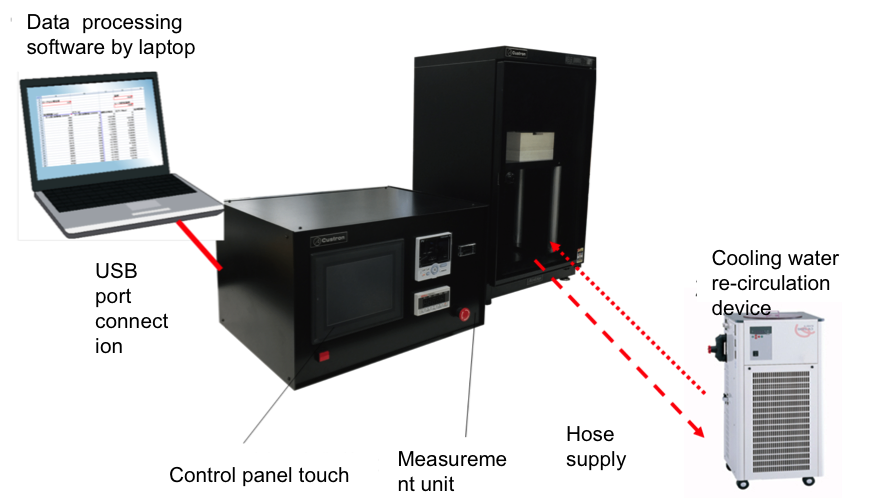

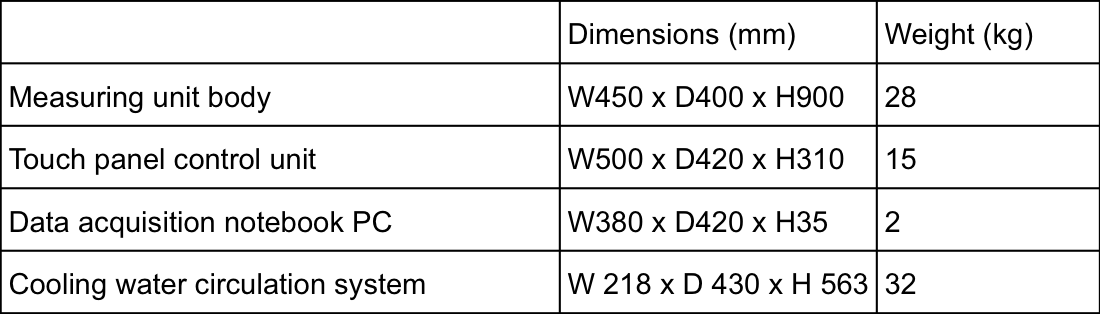

Device Configuration

Overall Structure

Settings Input method by touch panel

- Data is automatically collected by PC in Excel (measurement up to 30,000 steps)

- Temperature setting, room temperature to 180 ° C (can be changed by option)

- Temperature rise setting can be programmed by the program temperature control

※ It may not be stabilized depending on the setting.

- Interlocking of irradiation device, temperature setting is possible

※ It may not be able to interlock by irradiation equipment.

Temperature Profile

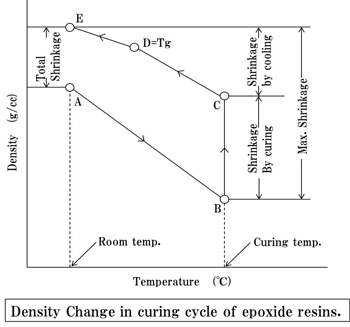

Contraction model of thermosetting resin

The liquid state A at normal temperature is heated and reacted at the curing temperature B, and the point at which the reaction is terminated is C.

The sample is allowed to cool from C to reach D (the glass transition temperature Tg of the cure system) before reaching room temperature E and the cycle is complete.

The shrinkage due to the curing reaction occurs between B and C, and the shrinkage due to cooling after curing is represented by C-D-E. However, since D corresponds to the Tg of this system, the contraction in the glassy region (<Tg) corresponds to DE, and the contraction in the rubbery region (> Tg) occurs between C and D .

The contraction between A and E is called total contraction, and the contraction between B and E is called maximum contraction. The shrinkage rate of a conventional thermosetting epoxy resin is to be measured between the points A and E.

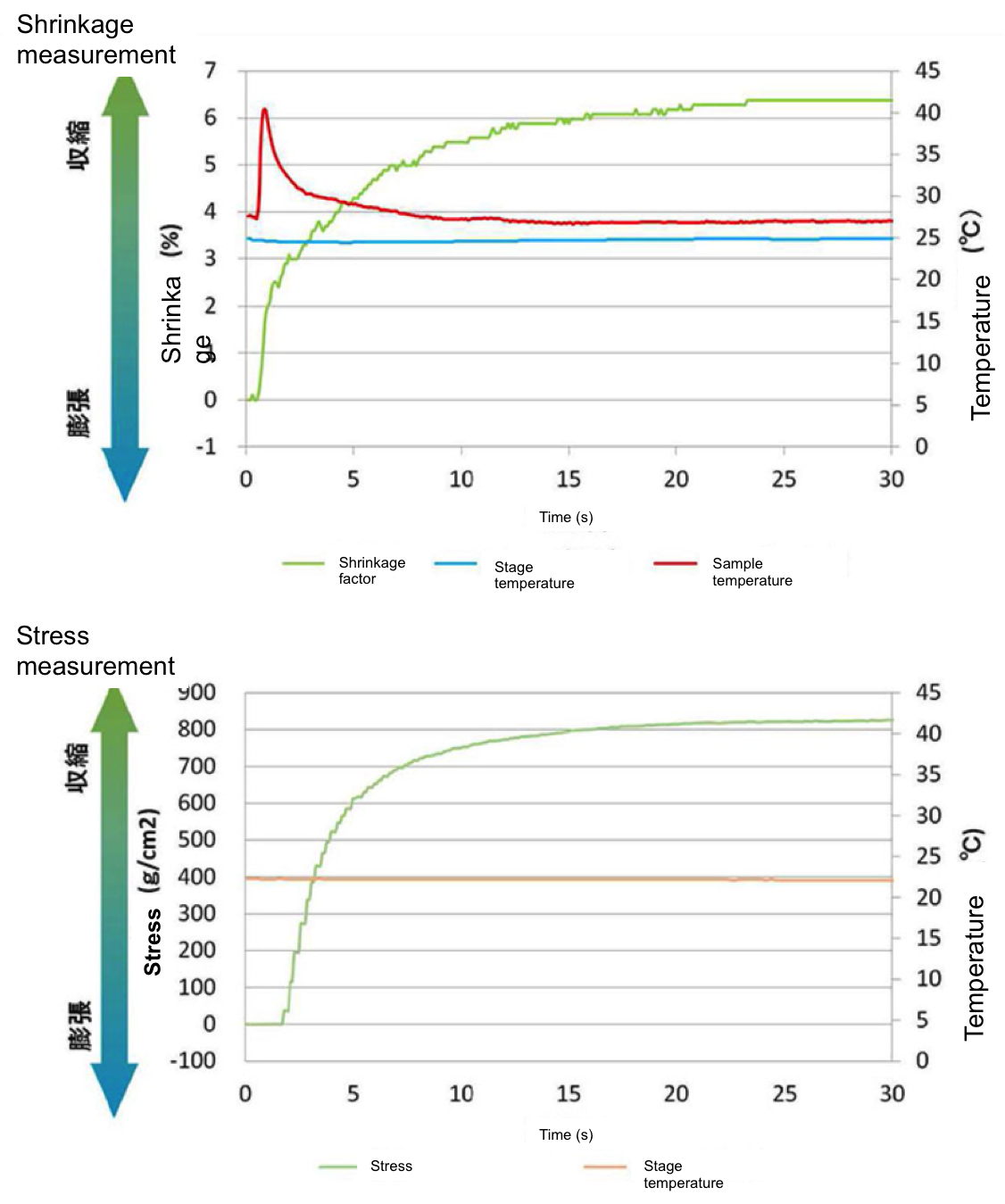

UV curing resin measurement example (acrylic resin)

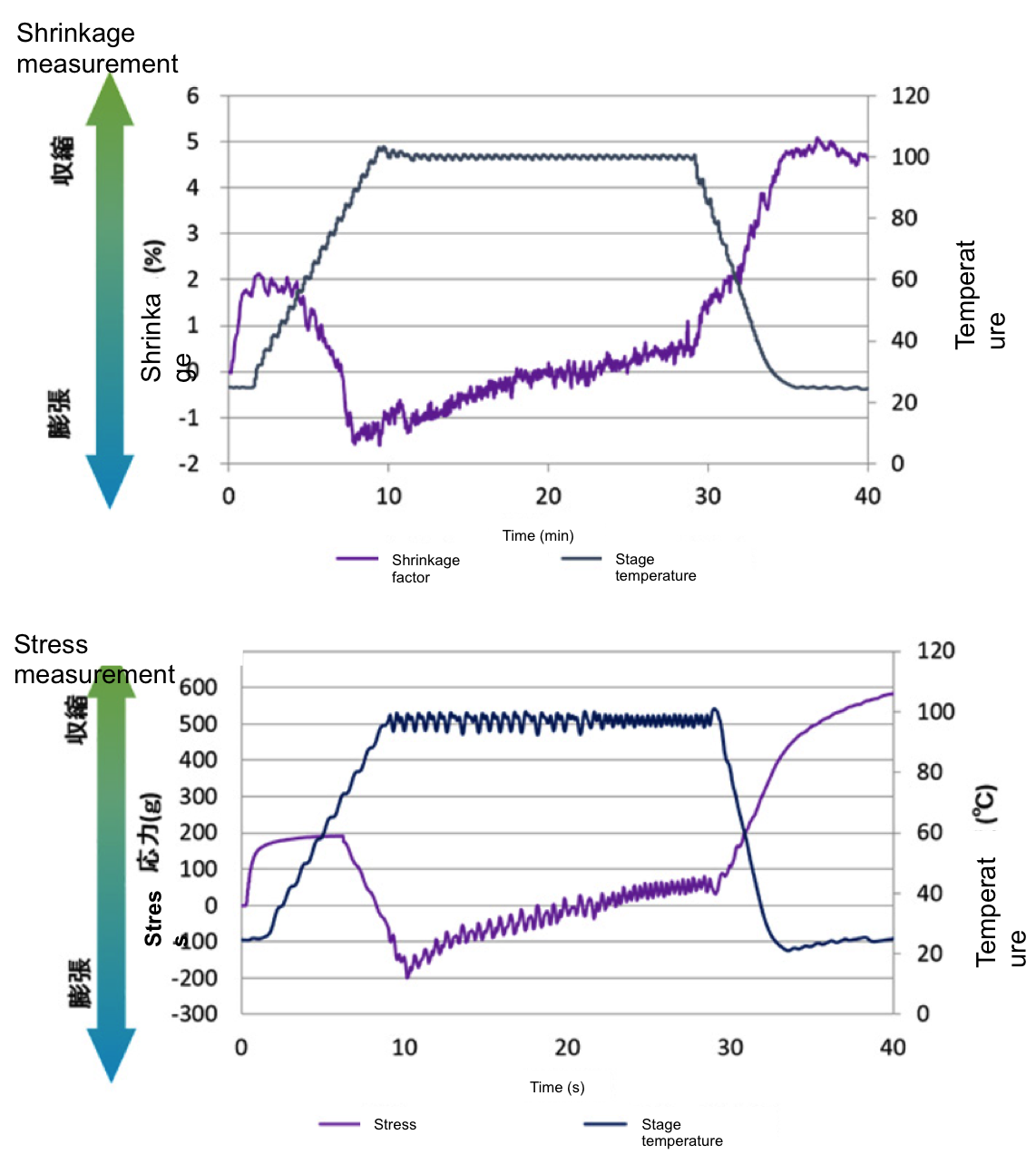

Thermosetting resin measurement example (epoxy resin)

UV + thermosetting resin measurement example (hybrid resin)

Product line up

Options

- Nitrogen purge function

- closed chamber

- Nitrogen flow meters

- IN inlet

- OUT outlet

- Flexible angle for fixing light guide

+ muff for fixing - UV irradiation external control function (ON, OFF)

- Various UV irradiation units

- Consumables (for initial set)

- Load cell probe finished product … 10

- Resin washers

■ t = 1 mm φ = 10 mm · · 3 sheets

t = 2 mm φ = 10 mm · · 3 sheets - Slide glass · 100 pieces

- Squeeze Hera · · 1 bottle

- Aluminum foil φ10 · · 10 sheets for shrinkage factor measurement

Consumables information

SPECIFICATIONS

Dimensions and weight

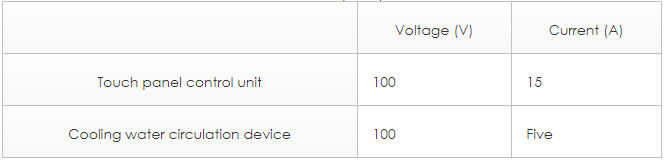

Power Capacity

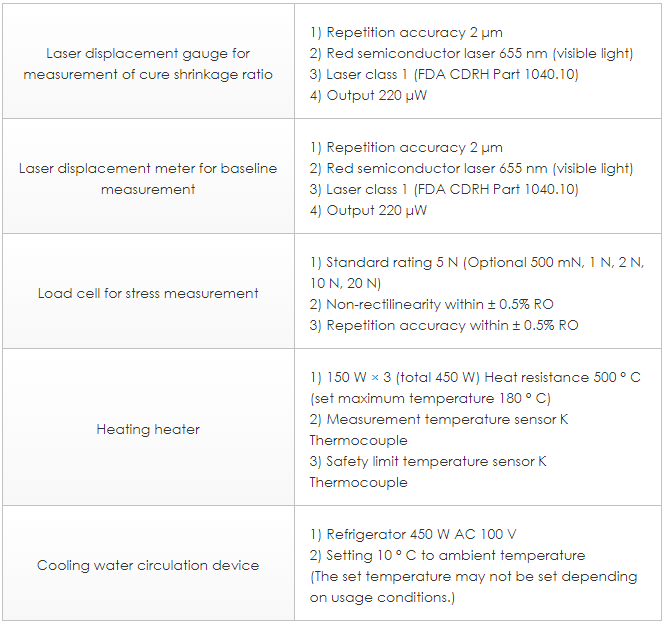

Performance

※ Specifications are subject to change without notice.

Please feel free to contact us for details.