CUREA

Sensor Image

Demonstration Video

Information

Patent No. 4185939

UV curing sensor – Curea catalogue download

【Curea Material】 New Curing Degree Estimation Method of UV Curing Resin

※ Product appearance and specifications are subject to change without notice

Features

Non-contact, nondestructive measurement

Its ability to measure without touching the sample allows inline nondestructive inspection.

In addition, even if the sample is inserted in glass or film, such as film adhesion with UV curing resin, it is possible to measure as it is.

Real-time measurement

Ideal for inline inspection (analog output)

Measure under illumination

Stable measurement is possible even under indoor lighting and curing ultraviolet light.

The curing status can be measured while irradiating with UV light (for curing), and it is possible to observe changes over time.

Equipment can be selected according to the object being measured

We will measure the actual sample and select the model that matches the object to be measured.

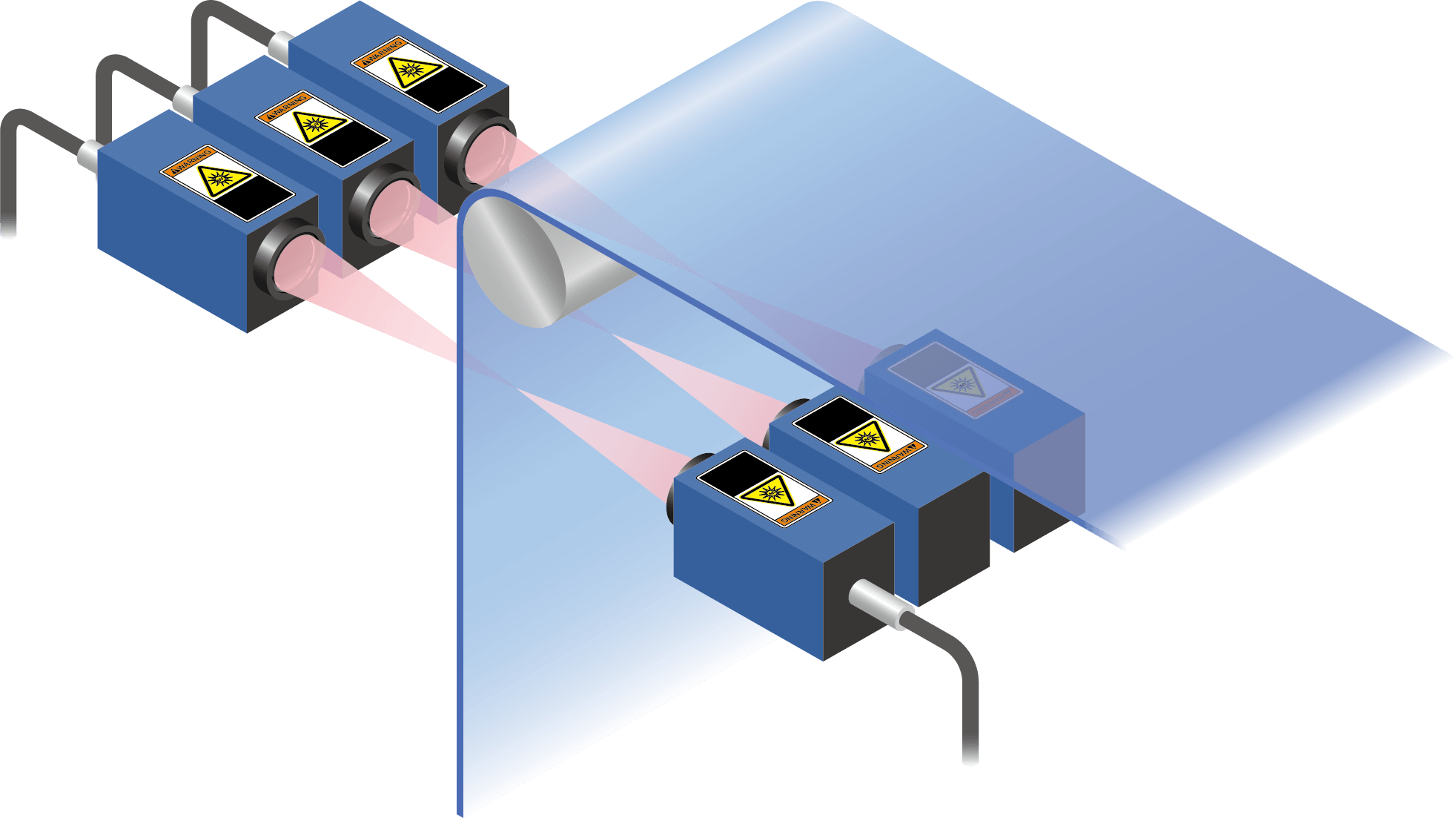

Small size and easy installation

Since the sensor head is small and lightweight (about 900g) , it can be mounted on an automatic stage or robot.

Applications

- UV adhesion

- UV coating

- Film laminate

- UV paint

- Nanoimprint resist

Detailed application of Curea is here

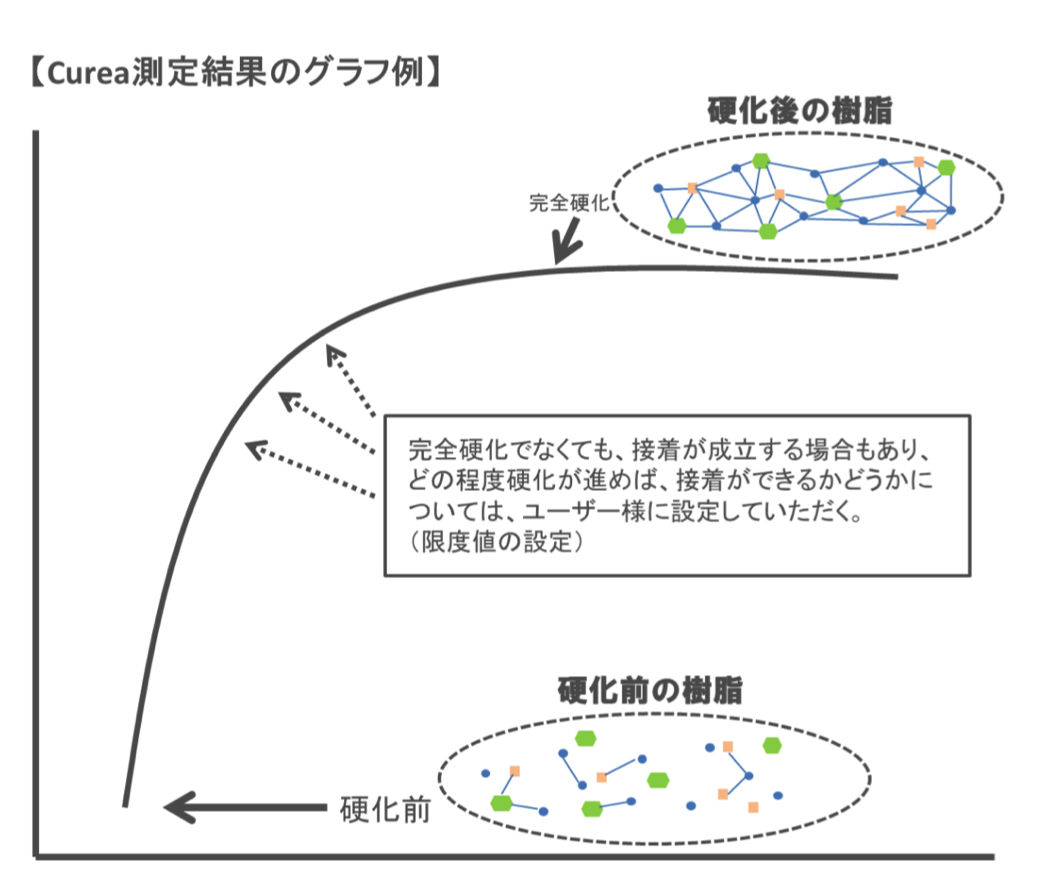

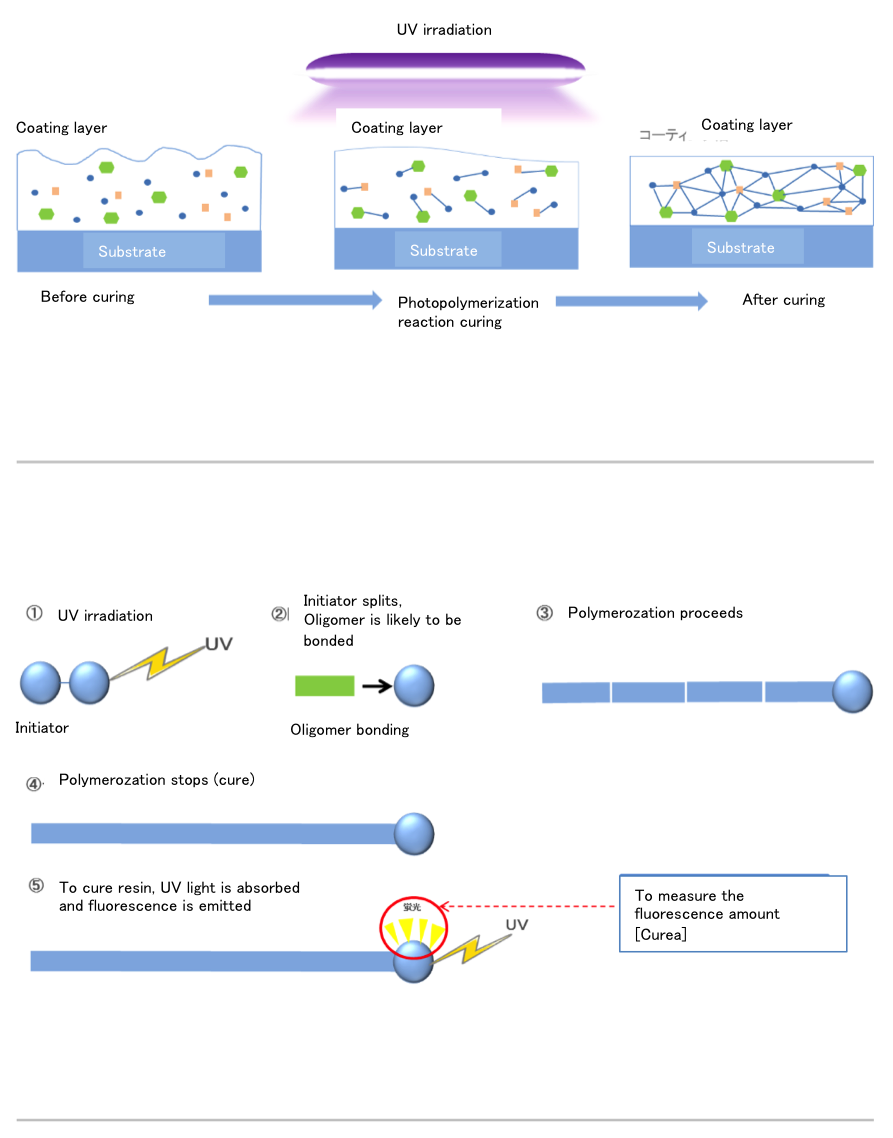

Measurement Principle

[Fluorescence] is emitted when the light energy (UV light) is absorbed, and the electrons in the molecule become excited and return to the ground state.

In this device, the built-in weak UV light is used as excitation light, and the fluorescence emitted from the subject is detected.

UV curing resins often measure the curing status because the fluorescence changes as curing proceeds.

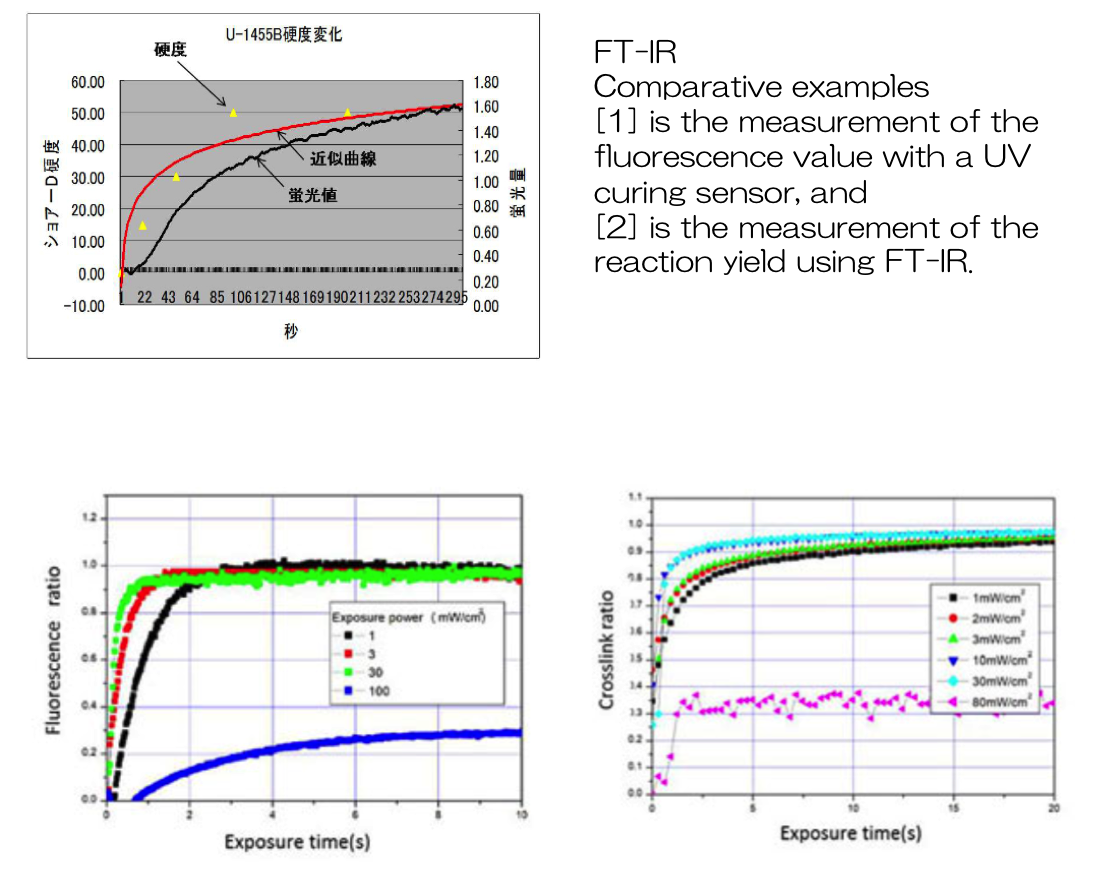

Measurement Examples

[1] UV measurement of curing sensor [2] FT-IR measurements

Comparing the two data, it draws a curve with the same tendency, and the use of a UV curing sensor makes it easy to obtain results similar to the analytical method.

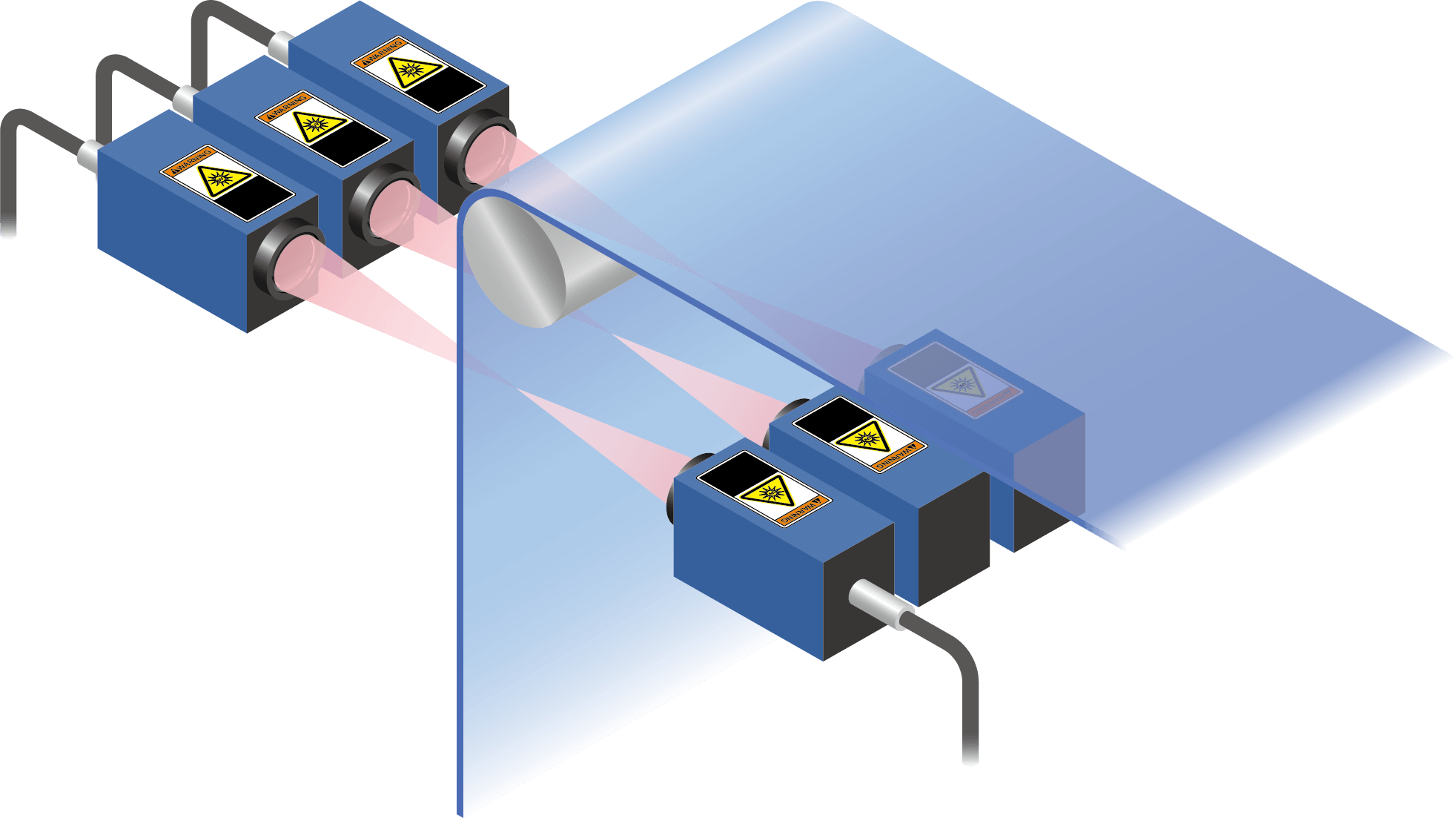

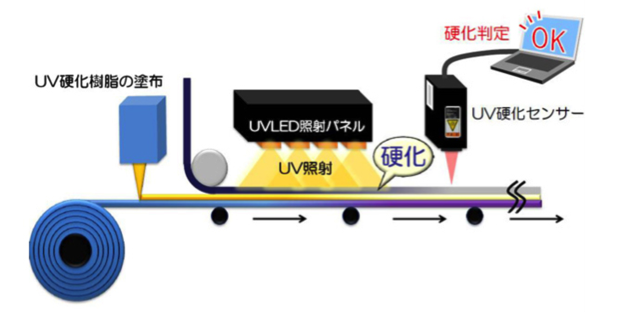

Installation Inline Examples

Example of use of [rolled sheet laminated products] in a production line

Production control: Curing judgment inspection of UV curing resin used for 【Laminated sheet laminated products】

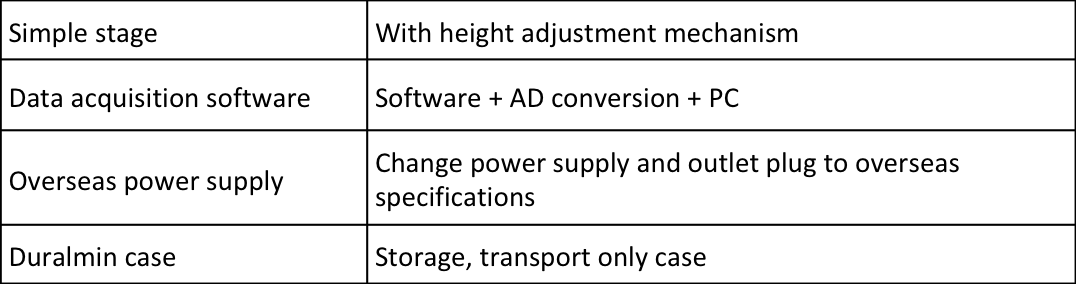

Options

For the automatic XY stage type for mapping , see UV curing sensor + automatic stage mapping system .

Caisits Optional Products “Standard Fluorescent Substance”

Acroedge has started selling standard fluorescent materials and options for surface modified sensor “Caisits”.

This is a standard substance used for performance inspection at the time of shipment.

If you have a standard fluorescent substance, you can check at your preferred time whether it is within the tolerance of the sensor’s measurement reference value. It also leads to the early detection of equipment abnormalities, enabling high quality control to be maintained. Please feel free to contact us.

Video

Handling explanatory video is here ⇒

Information request / inquiry ⇒