Features

Continuous measurement inline is possible!

Unlike conventional viscometers for R & D applications, this device/apparatus can manage viscosity in real time in the manufacturing process as well as for R & D applications.

The ability to measure viscosity in real time contributes to stable manufacturing process control via control (PLC, etc.).

Hard-to-break rotation mechanism!

Unlike conventional rotary viscometers, the rotation mechanism is designed to deter breakage even if resistance is applied to the rotating shaft. Even if there is a sudden change in viscosity, etc., the drive torque is not loaded.

※ We do not recommend the use to give an impact intentionally.

It is flexible and possible to cope with various viscosity when using this device!

Small size, light weight, low price! & Simple explosion proof!

Definitely, at the manufacturing site as well as in the research and development field, viscosity management can be performed reliably and conveniently. Inert gas can be used as a simple explosion proof by flowing in positive pressure.

With this one unit, stable viscosity measurement up to the viscosity of MAX 30,000 cps is possible.

With this one unit, stable viscosity measurement up to the viscosity of MAX 30,000 cps is possible. Anyone can use it easily by using a cone rotor that matches the viscosity and material characteristics.

※ Not only the shape of the rotor but also specification of the material is possible (necessary to be met)

Application

- Pigment, ink

- Food and beverage

- adhesive

- petroleum

- Ceramic slurry

- Culture / bioprocess

- Battery material

- Cosmetics / Pharmaceuticals

- Colloids in general

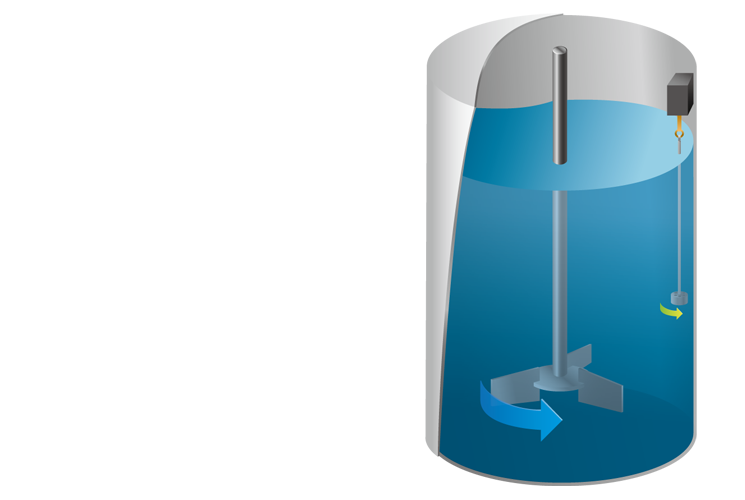

Example of Use

Stirring tank, real-time viscosity monitor of plating tank

Real-time viscosity monitoring is possible without taking up space in the stirring tank and culture tank used at the production site. Since the viscosity is measured in real time, even if viscosity fluctuations occur, discharge parameters are send to the dilution and raw material controls, enabling stable production at all times.

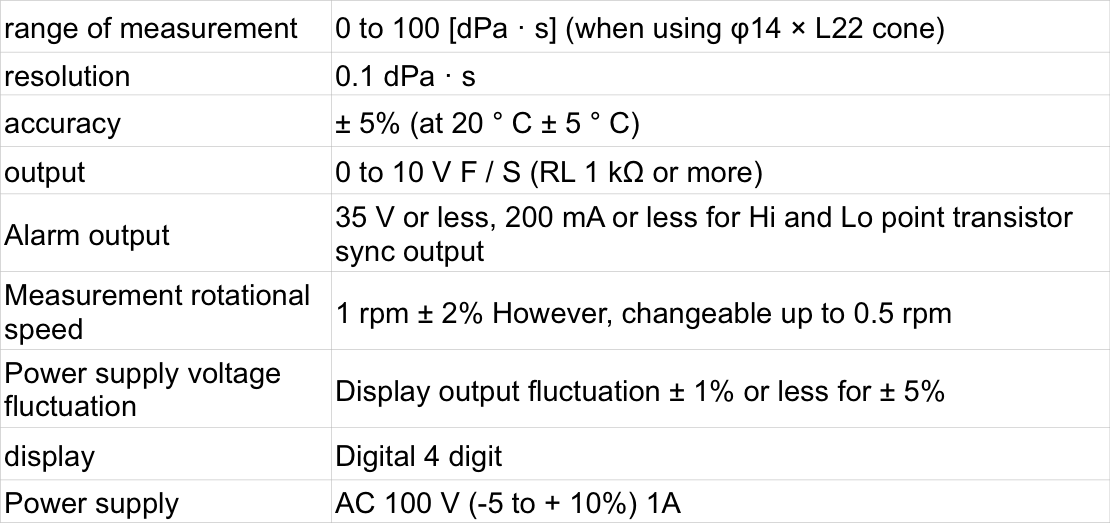

Specifications

Basic configuration

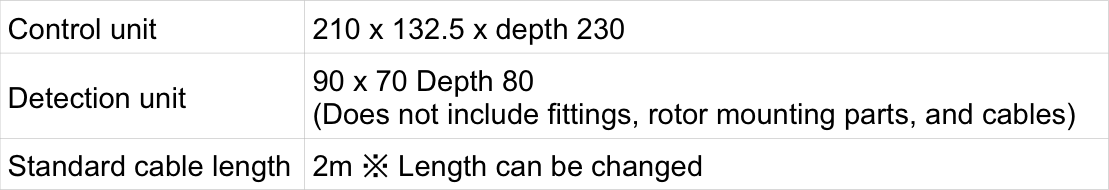

This viscometer is separated and configured into the main body and detector (see the photo), so it is easy to install at the viscosity measurement location.

The detector also has an air (nitrogen) purge fitting attached.

Size

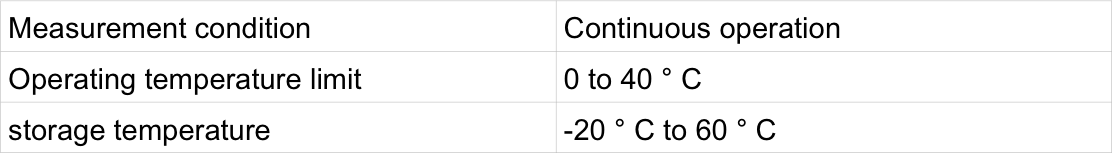

Terms of use

Performance